As you start sourcing metal for your next project, you know how crucial it is…

Understanding Metric Stainless Steel: Sizing, Grades, and Applications

For many applications, stainless steel is the best option, thanks to its corrosion resistance, wear resistance, and ease of maintenance. However, when sourcing stainless steel for your next project, you may notice that some varieties come in metric sizes while others use imperial units.

If you’re confused by the choices, now is the best time to learn everything there is to know about metric stainless steel, specifically how this material is sized, graded, and used in industrial and commercial practices. Knowing the intricate details of this metal can help you make the best choice for your needs.

What is Metric Stainless Steel?

Metric stainless steel is functionally identical to regular stainless steel, but it’s measured and cut into metric dimensions, not imperial. So, instead of seeing inches and feet when comparing sizes, you’ll see millimeters, centimeters, and meters.

The primary reason for the difference in stainless steel is that most countries use the metric standard. So, it’s much easier to build pieces and equipment that fit international standards and regulations.

Your Guide to Understanding Metric Stainless Steel

Although metric stainless steel is functionally identical to other types of stainless steel, it can still be tricky to find what you need for your project. Here’s a quick overview of your challenges when sourcing metric stainless and how to overcome them.

Sizing

As we mentioned, this type of steel is measured in millimeters, centimeters, and meters. But what if you’re used to the imperial standard? Well, one millimeter is equivalent to 0.0394 inches, and one inch is just over 25 millimeters. Unfortunately, there’s no one-to-one conversion rate, so you’ll have to adjust the material as necessary during your project.

As we mentioned, this type of steel is measured in millimeters, centimeters, and meters. But what if you’re used to the imperial standard? Well, one millimeter is equivalent to 0.0394 inches, and one inch is just over 25 millimeters. Unfortunately, there’s no one-to-one conversion rate, so you’ll have to adjust the material as necessary during your project.

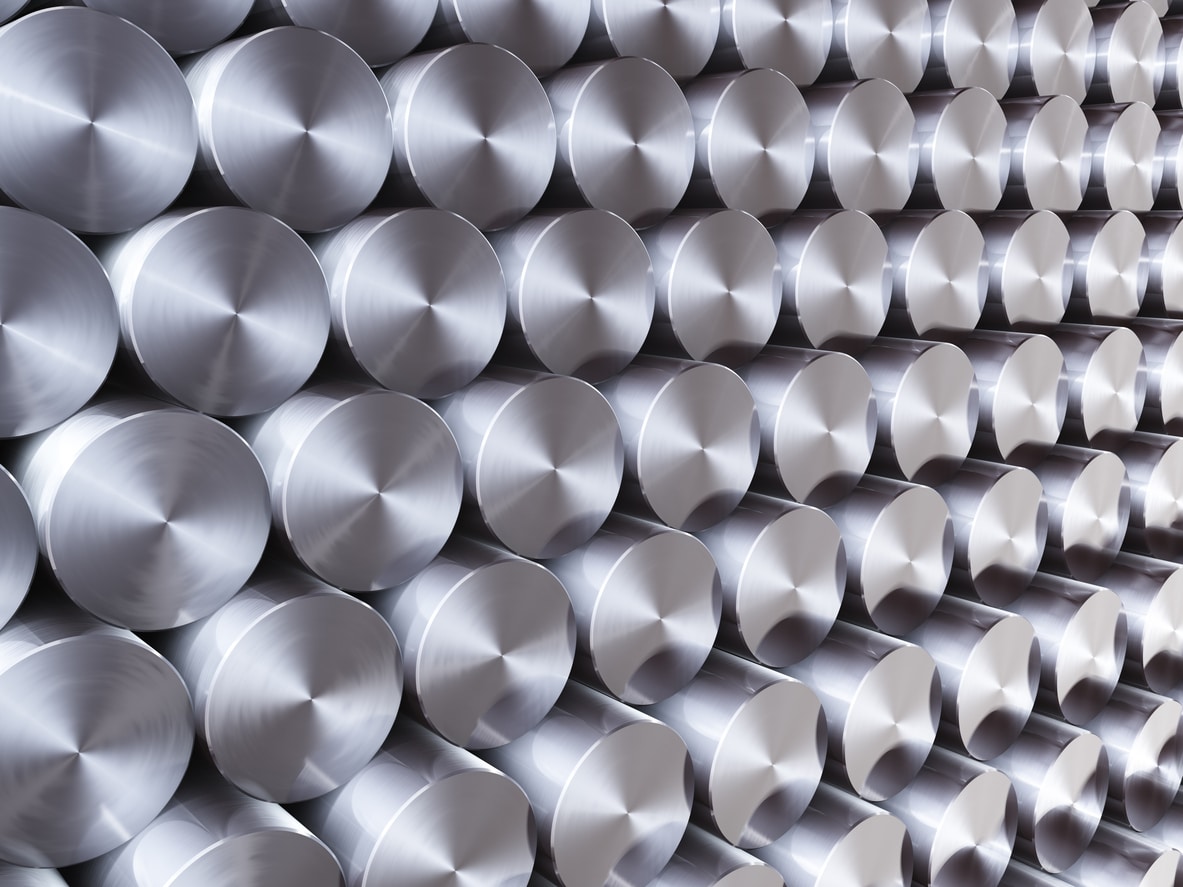

Metric stainless steel can come in different shapes, but the three most common are flat sheets, rounds, and square bars. When sizing rounds, the number of millimeters refers to the diameter. When sizing flats, the dimensions will refer to the length and width. Square bars can be solid or hollow; the number refers to the width.

But what about length? Metric stainless steel can come in pre-cut lengths, or buy custom sizes as needed. At Specialty Steel, standard bars are 10/13 feet random lengths. Although the price is higher for customized materials, doing so will help save you a lot of time and resources later on for machining, so you might even save money in the long term.

Steel Grades

As with any stainless steel, metric stainless is graded based on its chemical composition, molecular structure, and magnetic properties. Broadly speaking, all stainless steel can fall into one of three grades:

- Austenitic – This type of stainless steel has a face-centered cubic (FCC) structure, making it highly corrosion-resistant and non-magnetic. Two of the most common stainless steel grades, 304 and 316, are austenitic.

- Ferritic – Unlike austenitic stainless steel, ferritic metals are magnetic and contain high amounts of chromium and low amounts of carbon. This metal uses a body-centric cubic (BCC) structure, making it impossible to harden with heat.

- Martensitic – This type of stainless steel uses a body-centered tetragonal (BCT) structure, which makes it magnetic and very durable. Martensitic stainless steel is heat-hardened and has high amounts of chromium for better corrosion resistance. This metal also has a relatively high carbon content.

Austenitic stainless steel grades are widely used in multiple industries, such as food service, automotive, and medical. Ferritic stainless steel grades are much less common but can work well for some automotive parts (such as exhaust systems) and decorative architectural elements.

Finally, thanks to their hardness, durability, machinability, and wear resistance, martensitic stainless steel grades are widely used across industries. Common martensitic grades include 410, 420, and 440A.

Applications of Metric Stainless Steel

Typically, the best time to rely on metric stainless steel is when you’re working on projects that adhere to international metric standards. Some examples can include:

- Automotive Parts – Because cars and car parts can be used in various countries, it’s best to use metric stainless steel to ensure standardization between manufacturers and suppliers.

- Engineering – Many engineering projects utilize metric measurements for greater precision and accuracy.

- Science – As with engineering, scientific projects utilize precise metric measurements, so when deploying stainless steel for scientific equipment, it’s best to rely on pieces that are already in metric.

But finding the correct sizes is just the beginning. Sourcing high-quality stainless steel is imperative for all kinds of projects and industries. This material is typically deployed in the following fields:

- Medical – Medical devices and equipment are often made with metric stainless steel because it’s naturally antimicrobial and easy to clean. Even when pieces are exposed to pathogens and bodily fluids, they won’t lead to cross-contamination.

- Food Service – Almost all food service equipment is made with stainless steel for the same reasons as the medical industry. Not only is the surface of stainless steel easy to clean, but it can also withstand the wear and tear of food service operations, including cuts and scrapes.

- Automotive – Thanks to stainless steel’s abrasion and impact resistance, it works well for automotive parts and systems. These pieces can look visually impressive, especially if the metal has added chromium.

- Marine Environments – Most metals corrode easily when exposed to marine environments, but stainless steel is naturally corrosion-resistant and lasts much longer.

Buy Your Metric Stainless Steel From Specialty Steel

Now that you know the fundamentals of metric stainless steel, you can start ordering your pieces from Specialty Steel. We’re committed to providing high-quality, traceable materials for almost all projects, and our customer service team is always available to help.

If you’re used to using imperial sizes for your stainless steel, we can assist you in finding comparable sizes in metric. Since we offer customized sizing, you can get the precise dimensions necessary for your project. Contact us today to help you get the most out of your next metric stainless steel order.