When you need steel for your next project, you must ensure the material is built…

4140 Steel Annealing vs. Heat Treating: Key Differences and When to Use Each

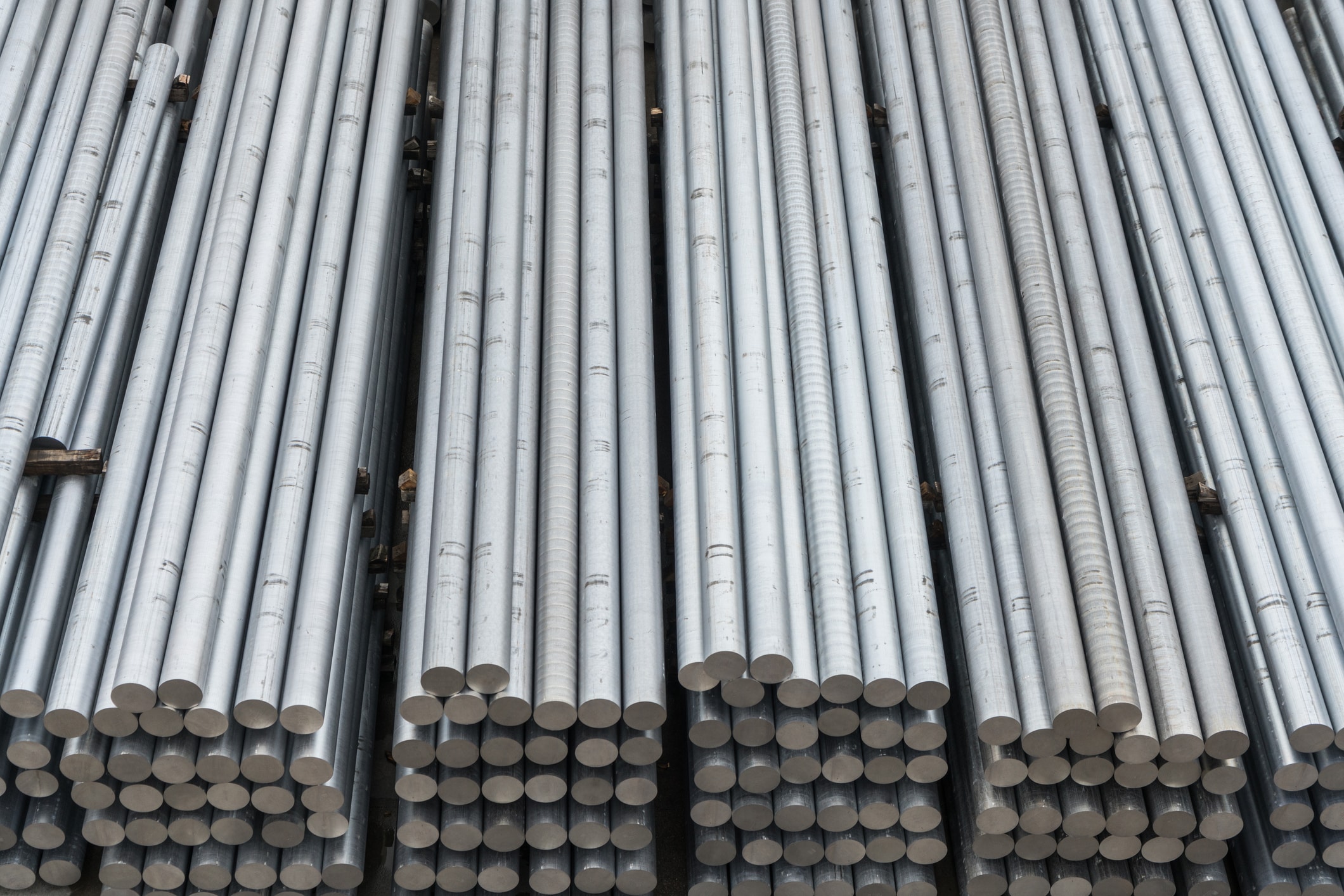

Although 4140 steel is already a tough and versatile alloy steel, it’s not exactly ready to use right “off the rack,” so to speak. Whether you’re buying 4140 bars or rounds , you’ll need to work with the material to ensure it works perfectly for your project. Two common methods for adjusting steel are annealing and heat treating.

Broadly speaking, 4140 steel annealing is designed to make the metal easier to machine and form into different shapes. Heat treating, however, is used to make the steel harder and more wear-resistant.

Understanding these processes enables you to use them at the right time to enhance your project and ensure long-term success. So, let’s break down the specific procedures for 4140 steel annealing and heat treating, and when they work best.

What is 4140 Steel Annealing?

4140 steel consists of a tight network of crystalline structures that form the “grain” of the metal. As you might imagine, uniformity makes a huge difference, as an uneven grain may cause stress within the metal, making it weaker and more brittle. Similar to how a knot in a piece of wood might reduce its hardness.

Annealing is the process of heating steel to just below its melting point. By doing this, the crystalline structures “reset,” meaning any imperfections or uneven sections dissipate naturally. However, to ensure the uniformity remains consistent, the metal must be cooled at a specific rate. Otherwise, new imperfections can form as different sections of the material cool faster than others. Typically, annealed steel either cools inside the furnace where it was heated, or it’s submerged in something like oil or sand to ensure consistent results.

Overall, think of steel annealing as “resetting” the metal to a clean, uniform structure. Another way to put it is that annealing “softens” the metal to make it easier to work with.

What is Steel Heat Treating?

Although annealing involves heating and cooling steel, it is a very specific process meant to yield a specific result. Heat treating, on the other hand, is designed to strengthen the material to make it tougher and more durable.

Typically, heating steel to a particular temperature helps solidify the crystalline structure so it’s more wear-resistant and can withstand impacts, scratches, and other environmental damage.

That said, heat treating still involves heating the material to a precise temperature, holding it at that temperature for a specific amount of time, and then letting it cool evenly. However, unlike annealing, heat-treated metal usually cools in room-temperature air.

When to Use Annealing

Annealing your steel is crucial for making it more malleable and machineable. For example, if you wanted to reduce the thickness of a standard bar or round, you’d have to anneal the material first before rolling it to a thinner gauge. If you didn’t anneal the steel first, it would likely break or warp, making it unusable.

Overall, annealing is a crucial step for turning standard steel sizes and gauges into precise pieces for your project. This way, you can buy bulk amounts and adjust them however necessary.

When to Use Heat Treating

The best time to use heat treating is often after you’ve machined your 4140 stainless steel. Heat treatments can increase the material’s hardness and durability because the metal is still relatively “soft” from annealing and machining.

FAQs About 4140 Steel Annealing and Heat Treating

Do I need to heat treat 4140 steel before using it?

Not always. Some 4140 bar stock comes pre-hardened and ready for machining. But if your project requires higher hardness or better wear resistance, additional heat treatment is a smart move to get the performance you need.

Should I anneal and heat treat all 4140 steel?

It depends on your application. Annealing makes the steel easier to machine or form, while heat treating boosts hardness and toughness. You might only need one of these processes—or both—depending on how you plan to use the material.

Can I anneal and heat treat 4140 steel more than once?

Yes, you can. It’s common to anneal the material before machining and then heat treat it afterward to improve strength. Just keep in mind that repeated cycles can change the steel’s grain structure, so it’s important to follow the right procedure.

Are there any downsides to annealing 4140 steel?

The biggest drawback is time. Annealing requires slow, controlled cooling, which can slow things down. But skipping this step when it’s needed can lead to warped or brittle parts, which costs you more time and money in the long run.

Buy Your 4140 Steel From Specialty Steel

Whether you need to anneal or heat-treat your 4140 steel, it all starts with using the right material. These processes can help fine-tune performance, but they can’t fix low-quality stock. That’s why it pays to source your steel from a trusted supplier.

At Specialty Steel, we provide high-quality 4140 alloy steel sourced from reputable, traceable mills. We understand the demands of machining, forming, and finishing, and we’re here to help you save time, reduce waste, and get the exact dimensions you need. We also offer custom cutting options for rounds, flats, and plates so you can start your project with material that’s ready to work.

Contact Specialty Steel today and let our experienced team help you find the right 4140 alloy steel for your next job.